How we Craft Quality

Langboard MDF

Langboard’s Medium Density Fiberboard (MDF) plant began production on September 1, 1998. Langdale Industries, Inc. purchased the plant, originally built in Las Vegas, New Mexico, in 1996. The plant was moved from New Mexico and reassembled in Willacoochee, Georgia. The plant was redesigned to streamline the production process and increase efficiency. The Langboard MDF plant operates 24 hours a day, 7 days a week.

The Langboard MDF

Langboard MDF is an engineered, wood-based panel. We use 100% Southern Yellow Pine which gives a light-colored MDF that works well in all applications. The chips and shavings are washed, classified, and refined with three high-energy Sunds Defiberator Refiners.

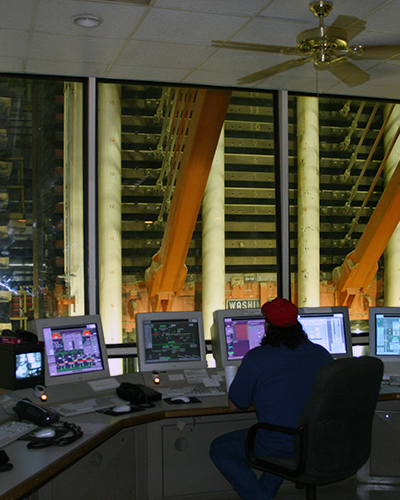

The fiber is formed into a mat and pressed in a twenty opening, Washington Iron Works platen press. This, along with state of the art controls give a more uniform density and a flatter profile. This also gives excellent results with shaping, routing, and overall machineability.

Our eight head, Kimwood sander along with a cross belt sander provides a smooth surface for laminating, with no grit lines. The Schellings Book Saw maintains clean cuts and accuracy that is setting the standard in our industry.

The Langboard MDF Quality Control Team is committed to high standards. Langboards’s state of the art process controls and testing procedures ensure a consistent product from one production run to the next. Along with our 100% customer satisfaction, we know that Langboard MDF will become your board of choice.

Langboard MDF and the

Every year since the 1930's The Langdale Company has planted more trees than it has harvested. As of 2009, the company planted its 100 millionth seedling, a feat duplicated by few in the industry. The Langdale Company is committed to growing forest products for our nation's future and the protection of the environment.

The wood for Langboard is grown in sustainable managed forests and tree farms, and the manufacturing of Langboard uses nearly 90% of the log. Langboard converts the remaining bark, saw trim, and sawdust into energy. Langboard exceeds strict quality standards for environmental safety set by the regulatory authorities.